The Allerton Waste Recovery Park went full operational at the start of March 2018.

We thought it would be good to spend a bit of time explaining what the plant does. A lot of the previous coverage on the plant has been around the politics – there is much more to it than that of course.

What goes in to the plant ?

Household waste – that’s the black bag waste and what goes in your black wheelie bin. It should be the waste that can’t be recycled. It’s a mixture of non-recyclable items, organic waste and other waste that maybe shouldn’t be in there. It takes 320 tonnes per year, that’s 320,000 tonnes that would have otherwise been put into landfill.

What comes out of the plant ?

Electricity – enough to power 40,000 homes a year

Steam/ gases – that’s what can be seen coming of the chimney stack

Particulates from buring – these are captured and sent to landfill

Recyclable material – it further sorts the received material and diverts it to recycling

Ash – this is what comes from burning some of the waste and is used for aggregate

Metals – these are recycled

Other material that can’t be recycled or otherwise processed, this is sent to landfill (less than 10% of material taken in)

Why is the plant important ?

- The plant processes 320,000 tonnes a year, with less than 10% from that then going to landfill. It has reduced the amount of waste just being buried in the ground by nearly 30,000 tonnes a year.

What about the pollution the plant produces itself ?

Burning produces gases, but what goes up and out the chimney is closely monitored. The burning process is at 850 centrigrade and interlocks are in place so that waste can not be burnt unless it reaches a minimum temperature. Ash is captured from the burning , that is used as aggregate. The exhaust flue gas is treated with hydrated lime and activated carbon before being filtered on its way to the chimney stack. The filtering captures particulates and the burning temperature and flue gas treatment reduces the gases produced (reduces Oxides of Nitrogen)

Does it smell ?

In the main processing halls it does, but outside the building on the day we were there was very limited odour. Environmental conditions can influence how much the plant smells, but there patrols around the perimeter, a number of times a day, checking for odour.

What is the process the waste goes through ?

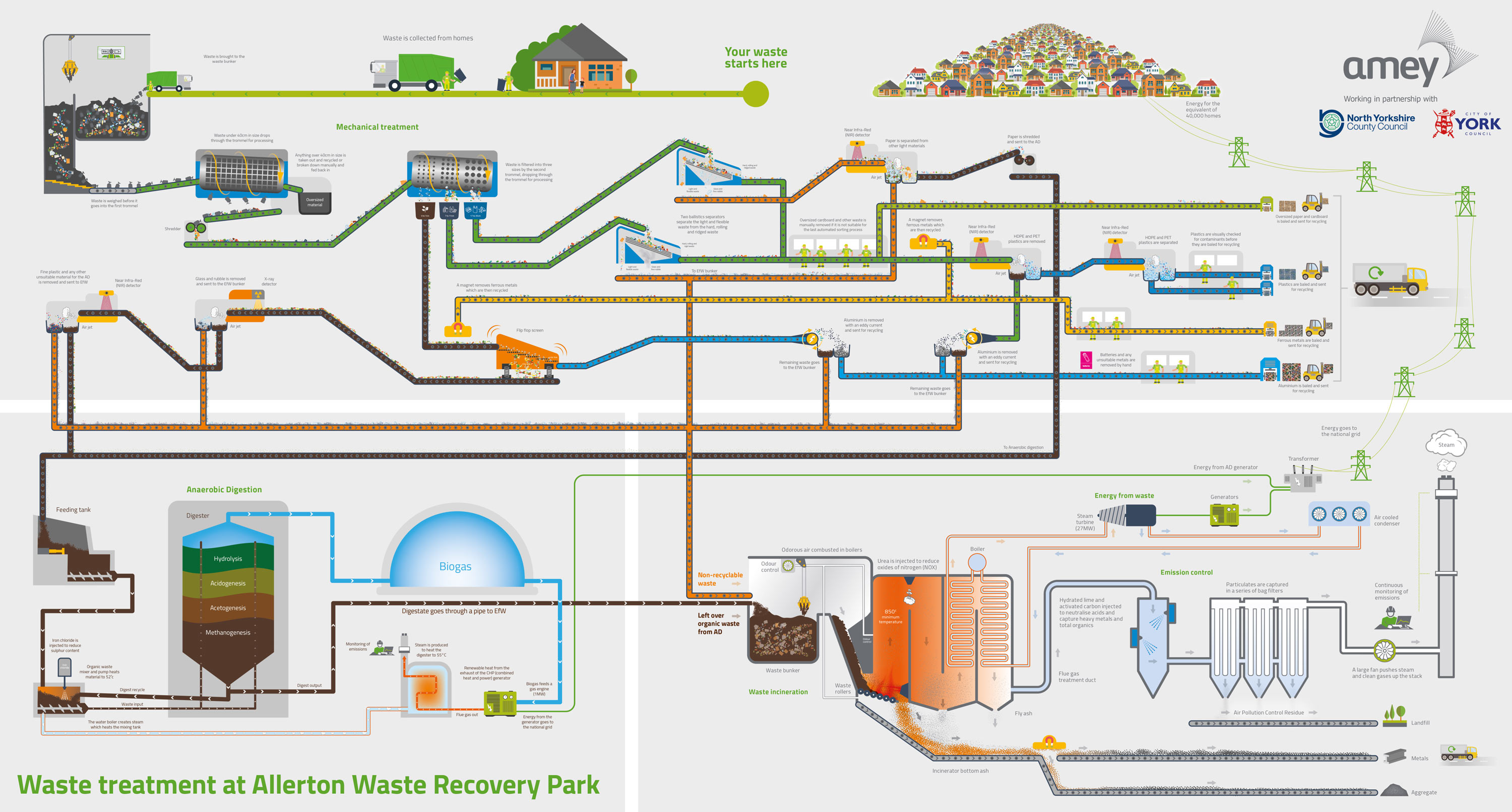

Waste is received by dust cart and taken into a large concrete hopper. As the plant operates during the daytime, along with service intervals, this means that waste can be received at anytime.

The waste is initially sorted, with anything over 40cm being taken out as oversized. The waste under 40cm is then shredded further before being sorted into three different sizes by a large rotating drum.

The waste then goes through various processes including magnets remove ferrous metals, an eddy current device aluminium and manual sorting. A proportion then goes to an anaerobic digester where, over a period of about a month, it is broken down further by bacteria.

From the digester, waste is then burnt at around 850 centigrade. The heat from the burning process also drives a turbine that generates electricity for export.

The operators of the plant, Amey, are also looking to do outreach work with local schools. They have plans to do school visits and host tours at the plant itself. This educational work is based around reduce, recycle and reuse.

Such a great shame that such a magnificent plant does not accept skip wagons which are serving the local area of all there waste removal needs as i was always under the impression it was going to but with a email sent to them it was clearly a no only the big companies are aloud in and smaller businesses as per normal forgotten about.Such a shame.